Safely Remove VOC’s from Wastewater!

Our Low Profile Air Strippers can efficiently remove almost 99% of most volatile organic compounds (VOC’s) from wastewater and contaminated groundwater, including Benzene, Toluene, Ethylbenzene, and Xylene (BTEX), as well as various Polycyclic Aromatic Hydrocarbons (PAH’s), chlorinated organics, and ketones.

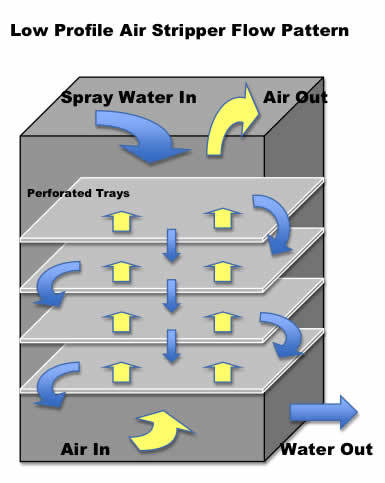

The air stripping process is relatively simple. The wastewater flows downward over horizontal trays as clean air pushes upward. This mixture of air and water forms a froth where the contaminants are removed. The VOC’s exit out the top of the Stripper and the clean water flows down into a sump. If necessary, the VOC vapors produced can be treated to ensure unsafe levels are not released to the atmosphere.

Advantages of the Low Profile Air Stripper:

- Small foot-print to fit into tight spaces

- Can be designed for in-door or outdoor applications

- Stationary trays reduce handling and maintenance time

- Easily handles variable flow rates

- No additional consumable costs

- Stainless Steel or Polyethylene construction

- TEFC air blower - sized to number of trays

Applications

- Groundwater Remediation

- Process Water Treatment

- Benzene Removal

- Wastewater Treatment

Depending on your application and level of VOC’s in the water, the Low Profile Air Stripper can be used as either a pre or post-treatment equipment to add to your water treatment system, or as a stand-alone unit.

Sizes range from 0.5 GPM to 1300 GPM. Additional options listed below can be easily added to optimize system performance for your particular application.

Series JLPS Low Profile Air Strippers

| Model | Flow Rate, gpm | # of Trays | Blower, cfm | Construction | Skid Dimensions, W x L x H range |

|---|---|---|---|---|---|

| JLPS-15-15P | 0.5-15 | 1-4 | 150 | Polyethylene | 42” x 72” x 53” - 78” |

| JLPS-22-15S | 0.5-22.5 | 1-6 | 150 | Stainless Steel | 38” x 40” x 57” - 105” |

| JLPS-50-3P | 1-50 | 1-5 | 300 | Polyethylene | 54” x 72” x 57” - 105” |

| JLPS-45-3S | 1-45 | 1-6 | 300 | Stainless Steel | 38” x 52” x 57” - 105” |

| JLPS-115-6S | 1-45 | 1-6 | 600 | Stainless Steel | 74” x 52” x 57” - 105” |

| JLPS-160-9S | 3-160 | 1-6 | 900 | Stainless Steel | 74” x 72” x 57” - 105” |

| JLPS-425-18S | 6-425 | 1-6 | 1800 | Stainless Steel | 130” x 44” x 66” - 121” |

| JLPS-550-24S | 8-550 | 1-6 | 2400 | Stainless Steel | 84” x 52” x 72” - 121” |

| JLPS-1000-36S | 12-1000 | 1-6 | 3600 | Stainless Steel | 150” x 81” x 72” - 121” |

| JLPS-1300-48S | 16-1300 | 1-6 | 4800 | Stainless Steel | 150” x 100” x 72” - 121” |

Additional Options

- Air pressure gauge

- Gravity discharge

- Steel frame

- EXP blower motors

- Discharge and/or feed pump, TEFC or EXP

- Blower start/stop panel only

- Main disconnect switch

- NEMA 4 control panel with level controls for pumps, alarm interlocks, motor starters, relays, alarm light, UL listed

- Control panel IS components for remote mounted NEMA 4 panel, UL listed

- Strobe alarm light

- Alarm horn

- Low air pressure alarm switch

- High water level alarm switch

- Discharge pump level switch

- Water pressure gauges

- Air flow meter

- Temperature gauges

- Line sampling ports

- Air blower silencer

Coalescing Systems

Coalescing Systems Ultrafiltration Systems

Ultrafiltration Systems Inclined Plate Clarifiers (IPCL Series)

Inclined Plate Clarifiers (IPCL Series)